Safety operation specification for folding machine

Release time:2020-06-17 17:55:00 Browse:81time author:Yihao Technology

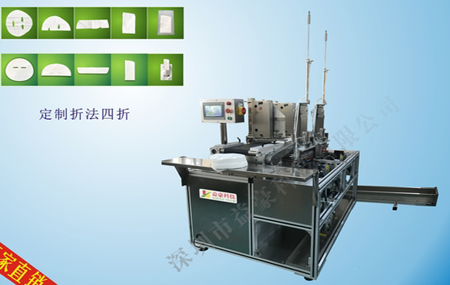

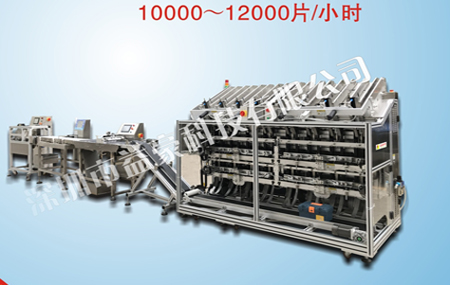

There are many types of folding machines for safe operation of folding machines. The most common folding machines in the market are bed sheet folding machines, linen folding machines, manual folding machines, and facial mask folding machines. The aforementioned folding machines are all industrial folding machines. In order to standardize the use of the folding machine and improve work efficiency, the following editor of the folding machine manufacturer will briefly describe the safe operation of the folding machine.

1. Please ensure that the folding machine is reliably grounded, and avoid the static electricity effect that causes the linen folded by the folding machine to adhere to the transmission roller, disturbing the photoelectric signal and affecting its normal working efficiency. Regarding its grounding, we can refer to the grounding conditions of other electrical equipment. Generally speaking, the two-eye copper nose of the grounded soft copper wire is fixed to the grounding rod by the electric clamp (the electric clamp has fixed and movable types). ) At the corresponding position, fix the monocular copper nose on the grounding wire to the grounding clamp or ground pin to form a complete grounding wire.

2. The power supply for this machine should be 380V+N-3PH-50Hz, and the cross-sectional area of the three-phase five-wire power supply must be greater than 1.5mm. The three phase wires of the machine are respectively connected to the U1, V1, and W1 terminals of the main power switch and the neutral wire is connected to the N1 terminal. The ground wire is connected to the ground terminal of the metal shell of the folding machine.

3. When actually using the folding machine, be sure to do a good job of its inspection to ensure that the machine is not abnormal, and we should forbid turning it on and using it if there is a fault or safety hazard.

4. Please set the corresponding working speed of the folding machine according to the ironing speed of the ironing machine used. Synchronize operations to avoid different speeds and affect work efficiency and the corresponding folding effect.

5. Pay attention to the direction of the conveyor belt of the folding machine when powering on, and avoid going backwards. Take the input conveyor belt as an example, it should be in the forward direction when it is fed directly to the folding machine. If the direction is not right, you can change the position of any two phase wires of the folder motor.

6. This machine needs a compressed air source with a pressure of 0.6-0.8Mpa, the outer diameter of the pipe on the machine is ф8mm, and the inlet of the water separator of the machine.

7. When the folding machine is actually used, when the machine fails, we can press the emergency stop button of the machine to stop it quickly. At the same time, stop the incoming linen from the ironing machine, and turn it on again after troubleshooting.

Shenzhen Yihao Technology Co., Ltd.

Shenzhen Yihao Technology Co., Ltd.