What kind of mask can the mask folding machine be used for?

Release time:2019-05-14 14:35:00 Browse:11time author:Yihao Technology

What kind of masks can the mask folding machine be used for? The materials of mask cloth on the market can be divided into: non-woven fabric, silk, tencel, bio-fiber, pulp fiber, deep-sea bio-fiber, bionic mask cloth, Binchang carbon mask cloth Wait. The mask folding machine is a fully automatic folding and bagging machine for saving mask manufacturers, which can be applied to most mask materials that exist on the market.

1. Non-woven fabric mask

The so-called non-woven fabric is also called non-woven fabric. It is composed of oriented or random fibers. It is a new generation of environmentally friendly materials. It is called cloth because of its appearance and certain properties. Non-woven fabric mask is based on non-woven fabric as the essence carrier. Most of the popular non-woven fabric masks on the market are mainly blended non-woven fabrics with a thickness of 30g-70g.

2. Silk mask

The main raw materials of silk mask are silk fiber and active silk protein. The silk mask was originally a bionic dermis used in the medical industry to deal with scalds-"silk film". The silk protein contains 18 amino acids (10 times the content of pearl powder) that are of great nutritional value to the human body.

3. Tencel mask

The raw material of Tencel comes from cellulose in trees, 100% pure natural materials, plus the production process of environmental protection without additives to form absolutely pure Tencel fiber. The Tencel mask can be completely degraded after about 12 weeks of use, forming water and carbon dioxide, which will not cause pollution to the environment.

4. Bio-fiber mask

Bio-fiber is one of the latest popular plant fibers in the world. It is made of 100% natural non-polluting deciduous trees, beech wood, etc., and is refined through advanced processes of desugar and fat removal. The bio-cellulose mask originated in Taiwan first, and it is a fibrous body made from natural fermentation of Acetobacter xylinum. It has a skin-like function, can permeate oxygen to isolate bacteria, and can be used as a covering for burns and scalds. It is a nano-level organic fiber derived from rigorous fermentation engineering. The content contains three parts: a net-shaped paper surface layer, a middle layer bio-fiber mask, and a nacre membrane bottom layer.

5. Fruit pulp fiber mask

Fruit pulp fiber mask is currently one of the most advanced mask cloth materials, plant extracts, more compliant than traditional masks, and has good breathability and no sticky feeling, which is the future development trend of mask cloths.

6. Deep sea bio-cellulose mask

Deep-sea bio-fiber is a new type of bio-fiber membrane, which has attracted wide attention since its introduction and was quickly recognized in the field of medical and health accessories. The precious "marine bio-fiber" is the only positively charged polymer material in nature, with a moisturizing power 7 times higher than that of cotton.

7. Bionic mask cloth

Bionic mask cloth is known as the first invisible mask. Combining the advantages of the previous masks, the bionic mask cloth introduced the bionic dermis, which was originally used by the medical community to deal with burns, "invisible film" into the beauty industry, which has achieved the top materials in the field of masks. "Stealth film" is a porous material with good air permeability and excellent water absorption, and can not be contaminated during the production process, so "stealth film" is specially used in postoperative wound dressing and burn wound dressing in European and American countries.

8, Binchang charcoal mask cloth

Binchang charcoal is obtained from charcoal made of hard ebony wood, qinggang wood and moso bamboo through carbonization at 1200 degrees high temperature. It has many fine pores and strong adsorption force. The membrane made of it has good ventilation, fine density, high The characteristics of strong elasticity and high water retention rate can release a large amount of negative ions to neutralize the positive ions generated by various dirt impurities in the skin, return the skin to a pure natural healthy balance, feel fresh and comfortable, and is known as the skin's scavenger.

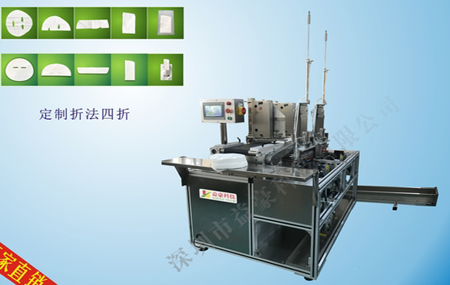

Mask folding packaging machine

Fold into the bag

Cut the mask cloth after folding into the packaging bag, divided into two methods: manual folding and automatic folding machine folding. Because the folding machine is expensive, most factories use manual folding.

Manual folding cloth: folding cotton by hand and bagging. The market price of the folded cloth is generally 3, 4, 5, that is, 3 cents on the first floor, 4 cents on the second floor, and 5 cents on the third floor.

Folding and packaging of facial mask is the most labor-consuming and time-consuming part of the facial mask production process. In order to save, many manufacturers will outsource this link to some small factories, and the so-called "small factories" are actually small workshops, a rental house, a dozen temporary workers, no environmental requirements, disinfection measures , Performance on a piece basis, and wages are settled on the same day. This is also the link where masks and masks are most likely to cause safety and quality problems.

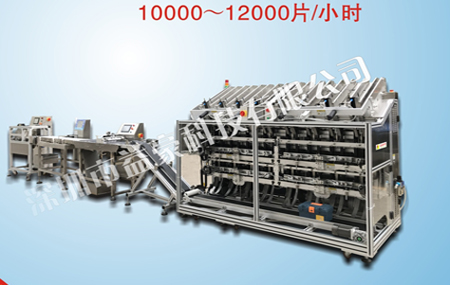

Automatic folding machine: automatic folding cotton forming, automatic bagging, lower bag opening and bag opening.

Features: Save manpower, high production efficiency, high product qualification rate, expensive, and regular mechanical maintenance. This link does not require a lot of manual participation, the construction period can be controlled, and the machine can automatically detect empty bags, which is not easy to cause problems.

Shenzhen Yihao Technology Co., Ltd.

Shenzhen Yihao Technology Co., Ltd.